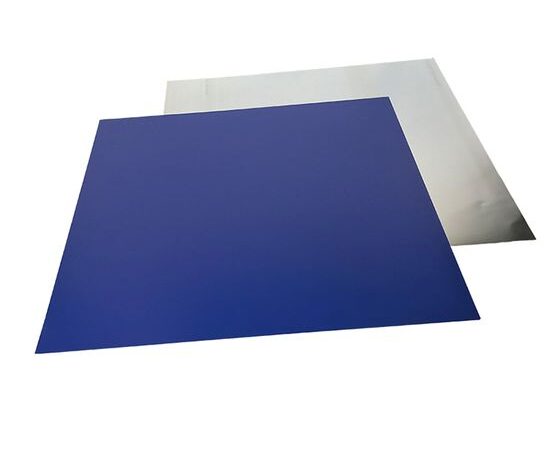

Why Choose Double-Layer CTP Plates Over Single-Layer?At Bab Al Rayan Inks & Printing Mat. Trd. LLC, we always strive to provide top-quality printing solutions that enhance efficiency and longevity. One of the most common questions we get from printers is: Why should we use double-layer CTP plates instead of single-layer ones? Here’s why double-layer plates are the preferred choice for professional printing.

- Superior Durability for Long Print Runs

Double-layer CTP plates are designed for high-volume printing, offering significantly longer run lengths without degradation. Single-layer plates tend to wear out faster, making them less suitable for large-scale jobs.

Solution: The top layer in double-layer plates provides a hard-wearing surface, ensuring stability for extended print runs. - Enhanced Image Contrast & Precision

In printing, clarity and sharpness matter. Double-layer plates offer better ink-water balance, resulting in sharper images and superior dot definition compared to single-layer plates, which can struggle with contrast and registration issues.

Solution: The secondary coating in dual-layer plates enhances dot formation, delivering crisp and clear prints. - Improved Chemical Resistance

Offset printing involves various chemicals, including fountain solutions and inks that can impact plate performance. Double-layer plates are more resistant to these aggressive substances, ensuring greater longevity and consistency in printing quality.

Solution: The second layer acts as a protective barrier, maintaining plate stability and performance over time. - Optimized for UV & LED-UV Printing

With the increasing demand for UV and LED-UV printing, plate durability under high-energy curing systems is essential. Single-layer plates tend to break down faster when exposed to UV curing, while double-layer plates maintain their integrity.

Solution: The additional layer enhances resistance to UV exposure, making them ideal for UV ink applications. - Higher Scratch Resistance & Press Stability

Handling and press conditions can sometimes cause plate damage, leading to print defects. Double-layer plates are designed to withstand mechanical stress, reducing the risk of scratches and surface damage.

Solution: The extra layer provides better protection, ensuring smooth ink transfer and minimizing press downtime.

Final Thoughts

If you’re looking for long-lasting, high-performance CTP plates, double-layer technology is the way to go. At Bab Al Rayan Inks & Printing Mat. Trd. LLC, we supply top-tier CTP plates that enhance print quality, durability, and efficiency.

For expert advice and premium printing solutions, get in touch with us today!

📩 Contact us for more details!

📍 Visit our store for the best printing materials in the market!